Are you tired of extraction results being compromised by poor-quality consumables? This can lead to wasted samples and unreliable data, creating major setbacks for your lab's critical work.

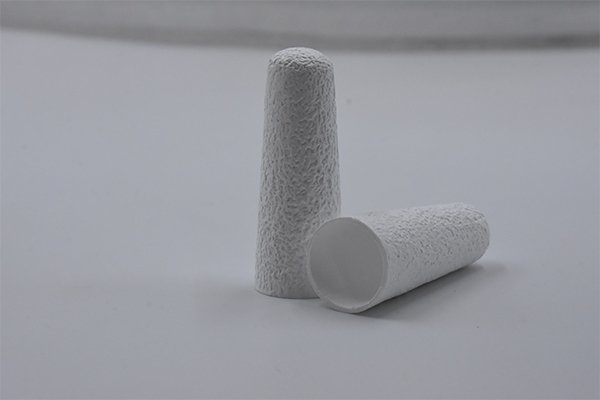

A high-performance Soxhlet extraction thimble[^1] ensures precise analysis by combining high-purity materials to prevent sample contamination[^2] with excellent mechanical strength[^3] to maintain integrity during the entire extraction process. This guarantees that your final results are accurate, reproducible, and completely trustworthy.

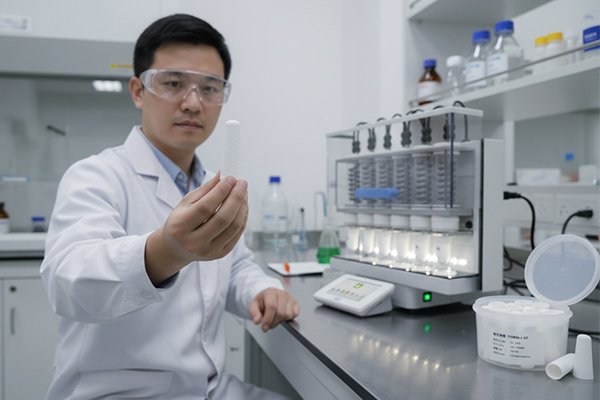

I've seen firsthand how the smallest detail can impact a big project. In the world of laboratory analysis, the extraction thimble is often that detail. It seems simple, but its quality is directly linked to the quality of your results. Choosing the right one isn't just about finding a part that fits; it's about building a foundation of reliability for your entire analytical process[^4]. Let's explore what you need to know to make the right choice every time.

Which Material is Right for Your Soxhlet Extraction?

Choosing the wrong thimble material can cause everything from process failures to contaminated samples. You need a material that perfectly matches your solvent, temperature, and analytical goals.

For standard extractions like fat analysis below 120°C, choose Cellulose thimbles[^5]. For higher temperatures or acidic conditions, use Glass Fiber. For extreme heat (up to 900°C) and inertness, like in high-temperature flue gas sampling[^6], Quartz Fiber is the ideal choice.

When we manufacture thimbles, the first question is always about the application. The material dictates everything. You wouldn't use a standard paper filter for hot acid, and the same logic applies here. Your choice directly impacts the success of your extraction. To help you decide, I've broken down the key differences based on what our clients, from food safety labs[^7] to environmental monitoring[^8] agencies, typically need.

Consider Your Sample and Solvent

The interaction between your sample, the solvent, and the thimble material is critical.

- Cellulose Thimbles: These are the workhorses for many labs. Made from high-purity cellulose pulp, they are perfect for standard Soxhlet extractions, especially in the food industry for determining fat content. They work well with most organic solvents but have a temperature limit of around 120°C.

- Glass Fiber Thimbles[^9]: When you need to go hotter or deal with acidic solutions that would degrade cellulose, glass microfiber is the answer. They are chemically resistant and can handle temperatures up to 500°C, making them great for environmental analysis of pollutants and industrial quality control.

- Quartz Fiber Thimbles[^10]: For the most demanding jobs, we have quartz. As my insights show, these are essential for high-temperature flue gas sampling[^6], often reaching 900°C. Their incredibly high purity and chemical inertness ensure that nothing from the thimble interferes with the analysis of trace elements.

A Quick Comparison

Feature Cellulose Thimbles Glass Fiber Thimbles[^9] Quartz Fiber Thimbles[^10] Material High-Purity Cellulose Borosilicate Glass Microfiber High-Purity Quartz Microfiber Max Temp ~120°C ~500°C ~900°C Key Use Food (Fat), Standard Organics Acidic Solvents, Air Pollution Flue Gas, Extreme Temps Purity Good High Ultra-High, Inert What Defines a Truly High-Performance Soxhlet Thimble?

Have you ever had a thimble tear apart mid-extraction? It's a frustrating experience that ruins the sample and wastes valuable time, forcing you to start all over again. A truly high-performance thimble is defined by three key factors: high-purity raw materials that won't leach contaminants, excellent mechanical strength to prevent tearing, and consistent sizing for a perfect fit in your extractor, ensuring efficient and reliable operation every time.

Precise Sizing of Soxhlet Thimbles

At our factory, quality control isn't just a final step; it's built into every stage of production. I often tell my team that we aren't just making parts; we're making certainty for the labs that depend on our products. A thimble that fails is more than just a defective product—it's a failed experiment, a delayed project, and a loss of confidence. That's why we focus so intensely on the core attributes that separate a standard thimble from a high-performance one. Let's look closer at what those attributes mean for your work.

The Importance of High-Purity Materials

The primary goal of extraction is to isolate a specific substance. If your thimble contains impurities—like binders, resins, or trace elements—they can leach into your solvent and contaminate the sample. This adds variables you didn't account for and can completely invalidate your results. We prevent this by using only the highest purity raw materials, whether it's cellulose pulp, borosilicate glass, or quartz fibers. Our manufacturing process is designed to be binder-free, ensuring that the thimble is chemically clean and won't interfere with your analysis, giving you a true and accurate measurement.

Why Mechanical Strength and Sizing Matter

A thimble needs to be strong enough to withstand the pressure and turbulence of the extraction cycle without breaking down. Our thimbles are constructed with uniform wall thickness and a robust structure to guarantee they remain intact from start to finish. Just as important is consistent sizing[^11]. A thimble that's too loose allows sample bypass[^12], leading to incomplete extraction. One that's too tight can choke the flow or be difficult to remove. We use precision manufacturing to ensure our thimbles have consistent dimensions, providing a snug, perfect fit that maximizes extraction efficiency and makes your lab workflow smoother.

Where Are These High-Performance Thimbles Used in Critical Industries?

Do you wonder if your specific application is common for these thimbles? It's easy to assume your process is too specialized, leaving you unsure if a standard solution will work.

These high-performance thimbles are trusted in a wide range of demanding fields, including environmental analysis for air pollutants, food safety for fat content, pharmaceutical R&D for purity testing[^13], and petrochemical analysis[^14] for additive concentrations. Their reliability makes them essential.

Key Application Areas

- Environmental Analysis This is one of the most demanding fields. We see our quartz and glass fiber thimbles used extensively for sampling emissions from industrial smokestacks. My insight about using quartz thimbles for high-temperature flue gas sampling[^6] is a perfect example. Their ability to withstand extreme heat and their inert nature are critical for accurately capturing particulates, dioxins, and heavy metals without contamination.

- Food & Beverage Testing Cellulose thimbles[^5] are the industry standard here. Their most common use is in determining the fat and oil content in food products to ensure they meet labeling requirements and quality standards. From potato chips to animal feed, our thimbles help ensure what's on the label is what's in the package.

- Pharmaceutical & Chemical Industries

In pharmaceutical R&D and chemical manufacturing, purity is everything. Our thimbles are used to extract active ingredients from plant matter, analyze polymer additives, or check for impurities in raw materials. The high purity of our thimbles ensures that the results of these sensitive analyses are never in doubt.

Conclusion

Choosing the right Soxhlet thimble is a critical step for accurate analysis. By matching the material to your application and demanding high quality, you ensure reliable, reproducible, and precise results.

[^1]: Explore how high-performance thimbles enhance extraction accuracy and reliability in laboratory settings.

[^2]: Learn about the impact of sample contamination on data integrity and how to prevent it.

[^3]: Understand the significance of mechanical strength in ensuring successful extraction processes.

[^4]: Understand the critical role of thimble selection in ensuring reliable analytical outcomes.

[^5]: Find out how Cellulose thimbles are utilized in various laboratory applications, especially in food analysis.

[^6]: Understand the complexities of high-temperature flue gas sampling and how thimbles help.

[^7]: Discover how Soxhlet thimbles are crucial for ensuring food safety and compliance.

[^8]: Learn about the applications of Soxhlet thimbles in monitoring environmental pollutants.

[^9]: Explore the benefits of Glass Fiber Thimbles for high-temperature and acidic extractions.

[^10]: Learn why Quartz Fiber Thimbles are essential for extreme temperature applications in labs.

[^11]: Discover how consistent sizing contributes to the efficiency of Soxhlet extraction.

[^12]: Learn about the implications of sample bypass and how to avoid it during extraction.

[^13]: Explore the significance of purity testing in pharmaceutical research and development.

[^14]: Find out how Soxhlet thimbles are used to analyze petrochemical additives and concentrations.